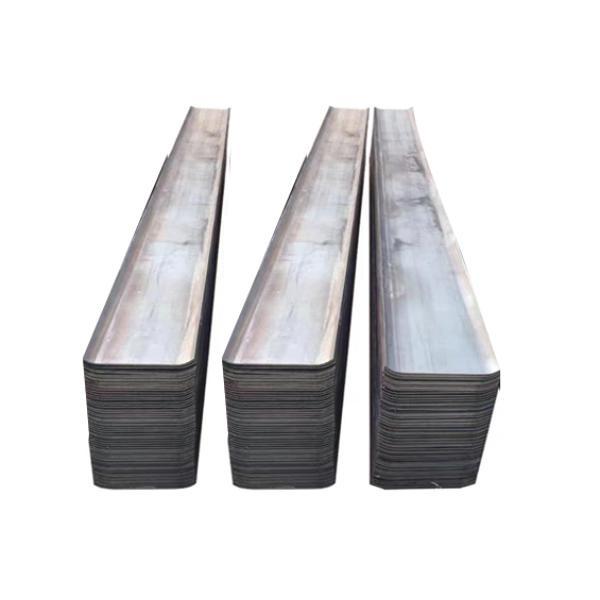

The main functions and uses of step-by-step tightening include improving work efficiency, saving work time, saving a lot of wood, and replacing traditional wire binding methods. Step by Step Tightening is a new type of construction equipment made of high-quality Q345 steel, with a simple structure, beautiful appearance, and strong practicality. It is mainly used in construction projects, especially in the early stages of bridge building construction, to reinforce columns or formwork on the main frame.

The specific uses of step-by-step tightening include:

Template reinforcement: In the early stage of bridge building construction, columns or templates are reinforced on the main frame to ensure the stability and safety of the structure.

Structural correction and reinforcement: widely used in the correction and reinforcement of structures such as beams, columns, stairs, etc., to ensure the accuracy and stability of building structures.

Save time and materials: Using step-by-step tightening can significantly reduce construction time, improve work efficiency, and save a lot of wood and other materials.

The design features of Step by Step Tightness include:

Simple structure: It consists of a steel rod and a movable head. The steel rod is usually made of high-strength steel, which has good toughness and torsional resistance.

Strong practicality: The structure is aesthetically pleasing and adaptable, suitable for various construction scenarios.

Easy to operate: By rotating the steel rod to clamp or release objects, the operation is simple and fast.

Production Strength

Handan Tengxuan Import and Export Trading Co., Ltd. is a production and sales enterprise integrating R&D, production and sales. The company was founded in 2005 and established in 2011. It is located in Yongnian, Hebei, China's largest fastener production base.

There are three major factories:

Factory 1: 500-ton hydraulic press, 300-ton, 200-ton, 100-ton friction press, multiple CNC lathes, thread rolling machines, stem shrinking machines, bending machines and other production equipment

Operation: hexagonal bolts, cylindrical head hexagonal bolts, steel structure bolts, torsion shear bolts, bucket-shaped wires, goose egg wires, square wires, ingot wires, countersunk single-ear wires, T-slots, plum blossom wires, horseshoe wires, fishtail wires, lining wires, plow tip wires, porcelain bottle wires, carriage bolts, middle hexagonal, trimming bolts, hook bolts, belt wires, double-reinforced wires, rail guard bolts, turnout bolts, subway connection bolts, pipeline bolts, high-speed rail bolts, extension bolts, coal mine bolts, tower bolts, flange bolts, sleeper bolts, pins, Rivets, reaming holes, backrest pins, single-head, double-head, anchor wires, various furniture screws, hexagonal nuts, welded square nuts, caps, female ball heads, triangular nuts, coal mine nuts, etc. Various special-shaped bolts and nuts can be customized according to drawings and samples.

Factory 2: Production of building aluminum formwork, wooden formwork, climbing frame, pipe gallery, earthquake-resistant and other auxiliary materials, through-wall tension screws, three-stage water-stop screws, pins, pins, square washers, pull tabs, tie rod nuts, mountain-shaped nuts, disc nuts, K-plate nuts, positive and negative buckle nuts, square buckles, small diagonal braces, tapered tubes, pipe clamps, circular hooks, steel supports, screw heads, hammers, hooks, screwdrivers, mold analyzers, nail removers, top removers, work benches, anchors, earthquake-resistant auxiliary materials.

Factory3: produces photovoltaic tie rods, U-bolts, aluminum alloy middle pressure blocks, side pressure blocks, triangular connectors, straight connections, bases, fixtures, photovoltaic brackets, aluminum alloy rails, plastic wing nuts, single-hole pressure plates, hot-dip galvanized bolts, stainless steel bolts, stainless steel expansion bolts, stainless steel nuts, flat spring washers, hot-dip galvanized bolts, nuts, flat spring washers, embedded anchor bolts, and customized various aluminum alloy parts. Company tenet: customer first, integrity-based, quality service, survival by quality, development by service, and efficiency by management. We sincerely welcome domestic and foreign merchants to visit our company for guidance and seek common development and create a better future.

FAQs

Q: When was Handan Tengxuan Import and Export Trading Co., Ltd. established?

A: Handan Tengxuan Import and Export Trading Co., Ltd. was established in June 4, 2024.

Q: What is the main business scope of Handan Tengxuan Import and Export Trading Co., Ltd.?

A: Our main business includes import and export of goods and technologies, sales of metal products, fasteners, hardware, building materials, and more.

Q: Where is Handan Tengxuan Import and Export Trading Co., Ltd. located?

A: We are located at Feiyu Bolt World, 40th Row A5, Linmingguan Town, Yongnian District, Handan City, Hebei Province.

Q: Does Handan Tengxuan Import and Export Trading Co., Ltd. have any affiliated companies?

A: While there are other companies with "Tengxuan" in their names in Handan, they are separate entities from Handan Tengxuan Import and Export Trading Co., Ltd.

Q: What is the business license number of Handan Tengxuan Import and Export Trading Co., Ltd.?

A: For specific information on our business license number, please contact us directly for verification and details.

TAGS:

Step by step

Classification

Message online

Note: Please leave your contact information and our professionals will contact you as soon as possible!

中文版

中文版 English

English Русский

Русский عربي

عربي